Chemineer International Corp. is the sole agent of Nanjing Tianhua Chemical engineering Co.,Ltd , Guangdong Province Foshan Pump Factory Co., Ltd.( Kenflo), Beijing Aerospace Petrochemical Technology and Equipment Engineering Corporation(BSPC), Nanjing Special Metal Equipment Co., Ltd. (SMEC), Nanjing Duble Metal Equipment Engineering Co., Ltd.

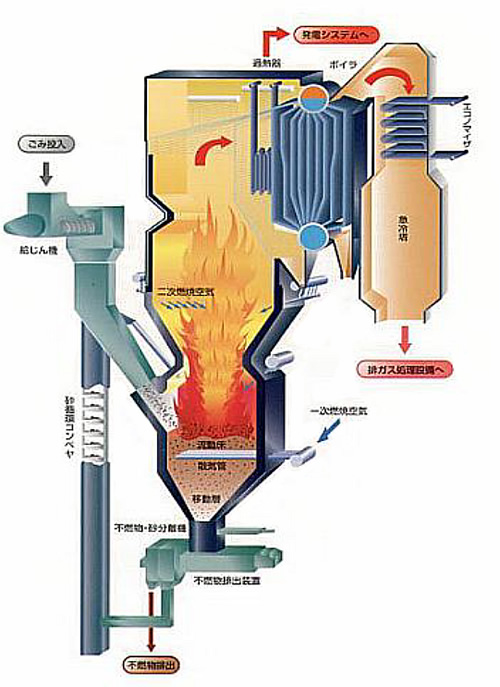

The main products of the companies that Chemineer is representing are consisting of vacuum pumps special material heat exchanger, stainless steel heat exchanger, special valves, safety valves, bagging machine, Environment-Friendly Incinerator Units, high speed pumps and compressors.

These products have been widely used in the field of petrochemicals, chemicals, refinery, synthetic fibers, steel, nuclear plant and sea water de-sodium projects...etc.

Engineering capability plus repair and maintenance have been the key factors of our services. Already, we has accomplished many successful after sales services, such as pre-commissioning start-up of new plants established in overseas plus maintenance of the already running units. Other services include repair and overhaul services, emergency trouble shooting, regular technical training and etc.

Whenever there is a need for pumps and/or chemical machines, you can contact us. The pollution free oriented products help keeping our environment from chemical emissions. Let Chemineer be your partner in making this world a better place to live in.

|

Product Introduction |

|

Beijng Aerospace Petrochemical Technology and Equipment Corporation |

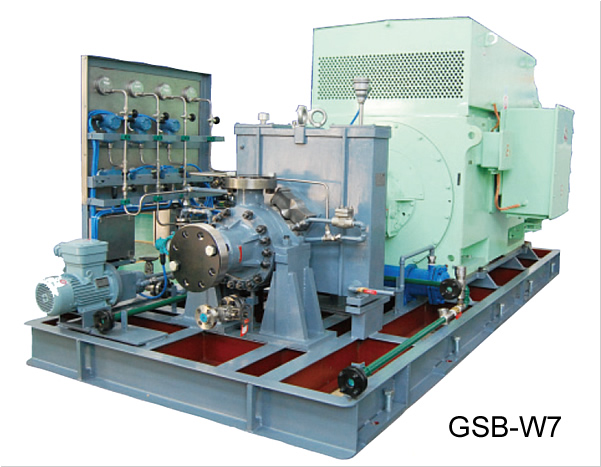

High-Speed Pumpss

|

|

|

|

|---|---|---|

| Max. Flow(m3/h) |

|

|

| Max. Head(m) |

|

|

| Max. Suction Pressure(MPa) |

|

|

| Max. Working Pressure(MPa) |

|

|

| Max. Motor Power(kW) |

|

|

| Temperature Range(°C) |

|

|

| Speed Range(rpm) |

|

|

|

|

|

|

|---|---|---|

| Max. Flow(m3/h) |

|

|

| Max. Head(m) |

|

|

| Max. Suction Pressure(MPa) |

|

|

| Max. Working Pressure(MPa) |

|

|

| Max. Motor Power(kW) |

|

|

| Temperature Range(°C) |

|

|

| Speed Range(rpm) |

|

|

Industry Flare

Horizontal High-Speed Centrifugal Pumps

Safety Valves

|

|

Packing System

|

|

|

|

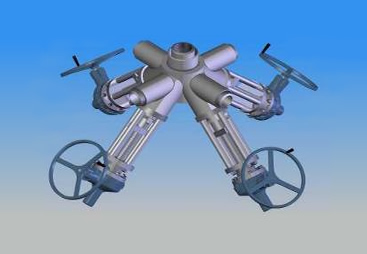

Special Valves

|

|

|

|

Nanjing Tianhua Chemical Engineering Co., Ltd. |

Major Products

|

|

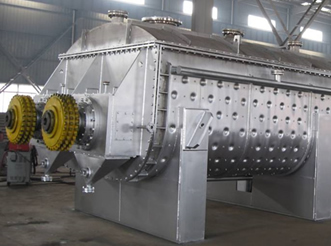

Paddle Dryer & Cooler

The NTCE Paddle Dryer is a machine used to heat treat powders, granulates, filter cakes and pasty products in a full-continuous process. The Paddle Dryer has a heated trough containing rotating heated paddle shafts. The product is fed into the front of the machine. The trough is oriented at a small angle of inclination, placed slightly in unloading position. The product moves to the outlet as a result of gravity. The paddles do not have a transport function. They are designed for maximum heat transfer. At the outlet side, the product moves out of the machine via the overflow unit.

The features of the Paddle Dryer are: Excellent control of the retention time and temperature. This results in a uniform product quality; No drying air required to dry the product; Hardly any dust production due to the slowly-turning paddle shafts; Better heat transfer due to the specially-shaped paddles.

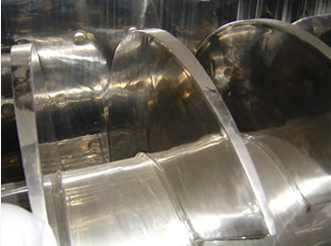

The wedge-shaped paddle ensures for excellent contact on both sides of the paddle and mixes the product in radial direction. In addition, the wedge-shaped paddle ensures for shear forces on the paddle surface and this keeps the paddle clean and contributes to improved heat transfer.

The applications for which this machine can be used include:

|

|

Rotary Stream Tube Dryer

Steam tube rotary dryer is a kind of indirect heat rotary dryer. The difference against the normal rotary dryer is that the former has steam tubes installed in the cylinder. The tubes are arranged as 1~6 concentric circles, intersecting the dryer, and supply the heat for the dryer. The carrier gas is utilized to take away the moisture generating in the drying process, and therefore making the materials dry. Since the carrier gas is consumed few, the drying effect of it can be ignore. The major parts of the steam tube rotary dryer are screw feeder, cylinder, heat exchange tubes and its support, steam chest, driving system, gear ring, rolling ring, riding wheel, catch wheel,feed end of cylinder, discharge end of cylinder, chassis, and lubricating system.

|

|

|

Nanjing Special Metal Equipment Co., Ltd. |

Heat Exchanger

SMEC is specialized at designing and manufacturing pressure vessels made of zirconium, titanium, nickel alloys, copper alloys, tantalum, stainless steels and their cladding materials. The main products of SMEC include reactors, heat exchangers, separators and storage tanks.

|

Guangdong Foshan Pump Factory Co.,Ltd |

Liquid Ring Vacuum Pump

Kenflo focused on the research of equipment application industry pump, has 50 years of pump product design and production experience, is China liquid ring vacuum pump's founder.

|

Hamada Boiler |

The remarkable achievement made by Hamada Boiler is in the area of small and medium size of Fluidized Bed Combustion Boiler of 1 ton to 40 ton/H capacity. Fluidized Bed Boiler has been somewhat a monopoly of the huge boiler companies and most of them produce above 40 ton/h capacity for power plant requirements. Hamada Fluidized Bed Boiler is for small and medium size where big giant boiler makers do not wish to accept orders or not capable to offer competitive price. Hamada Boiler have established unbeatable record of numerous installations of FBC Boilers in the Asian territories for the past years.

In the year 2000, several Japanese companies in Indonesia started to build own house coal fired power plant and Hamada Boiler received many repeat orders from those companies to install 35 and 75 ton/H capacity Circulating Fluidized Bed Boiler (CFBC). 4 power plants have been completed by the year 2006 and Hamada Boiler can now accept orders of CFBC as big as 135 ton/H 100 bar pressure and 530 oC steam temperature for power plant specification.

|

|

Jiangsu BOE Environmental Protection Technology Co., Ltd. |

BOEEP® volute Screw Press,which is a latest advanced sludge dewatering technique. It's characterized by small footprint and wide applications.Its can be used for different sludge in varieties of industries including petrochemical processing,light industry, electroplating, printing & dyeing, food & beverage, chemical fiber, paper-making, proteins, livestock, pharmacy and leather etc.It has been proved the best irreplaceable solution for the low-concentrate sludge and oily sludge.It also has gained high recognition from the governments, experts and users.

The major components are control cabinet, flocculation tank, dewatering part and filtrate collecting tank.The whole system is continous.

Features:

|

Dewatering Principle:Sludge will be transported to the dewatering to the dewatering department after being thickened in the thickening department.In the advancing process,great pressure has been produced because of the gradually decreasing filter spacing and screw distance, and the back platen clogging, Then the volume decreases continuously, and the purpose of fully dewatering will be achieved. |

|

.jpg) |

.jpg) |

.jpg) |

|

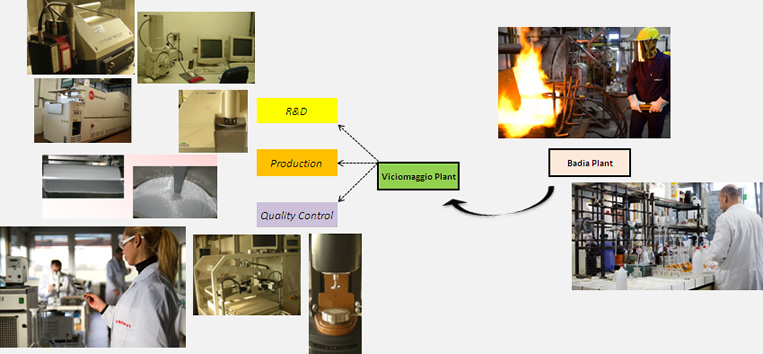

Chimet S.p.A |

Chimet's Thick Film Division, established in 1984, is a manufacturer of high quality precious metal powders and screen-printable pastes. Already a world leader in the automotive sector, Chimet's Thick film Division has gained significant market share in the photovoltaic and electronic industries.

|

Chimet's Thick film Division manufactures the following screen-printable products:

|

|

Welcome download file

Get TDS: Automotive ![]() 、Membrane

、Membrane ![]() 、PV

、PV ![]()