Mott, USA

|

Sintered Porous Metal Filter |

Brand: Mott Corporation, products- filters, sparger, disc, and flow restrictor, etc. Filtration, flow control, sparging, dispersion and shapes of porous metal.

|

|

Sinter, China

|

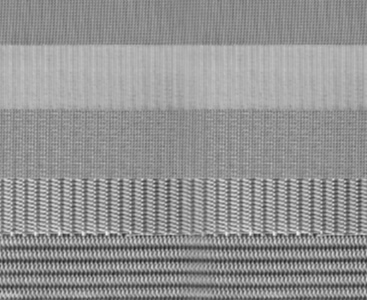

5-layers Sintered Mesh |

Five different layers of stainless steel wire mesh are combined, and sintered together through vacuum sintering, compressing, and rolling , forming a porous product.

The media grade from 1 micron to 100 micron, good strength ,steady, easy wash, heat resistance to 480C, corrosion resistance of SUS316L.

To utilize on cutting, bending, punching, stretching, welding.

Material: SUS304, SUS316, SUS316L.

Special: Alloy, Hastelloy, Monel, Inconel.

|

Type A Sintered Wire Mesh |

This is a standard combination of 5-layer sintered wire mesh which has the widest application. Five different layers of stainless steel wire mesh are combined, and then sintered together through vacuum sintering, compressing, and rolling, forming a porous product.

The standard materials are SUS304 (AISI304),SUS316(AISI316),SUS316L(AISI316L). Special Alloy Steel Hastelloy, Monel ,Inconel are acceptable base on customer's requirement .

The standard dimensions are 500x1000mm, 600x1200mm and 1000x1000mm, 1200x1200mm, and other dimensions in between are also available.

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

600 |

|

|

|

|

|

|

|

|

590 |

||

|

|

|

|

|

|

550 |

||

|

|

|

|

|

|

500 |

||

|

|

|

|

|

|

480 |

||

|

|

|

|

|

|

450 |

||

|

|

|

|

|

|

410 |

|

|

|

|

|

|

|

|

390 |

||

|

|

|

|

|

|

350 |

||

|

|

|

|

|

|

300 |

||

|

|

|

|

|

|

250 |

||

|

|

|

|

|

|

190 |

Note: The 6-layer sintered wire mesh is to add one layer of 12 mesh to the 5-layer sintered wire mesh. Its thickness is 3.5mm.And it has the higher anti-pressure ability.

|

Type B Sintered Wire Mesh |

This type of mesh is sintered together by many layers of plain-woven square mesh. Owing to the large opening ratio, the sintered mesh possesses good permeability, small resistance but large flow. It is mainly applied to filter kinds of air and liquid. It can be made according to the customer's request because every layer of mesh is alternative.

The standard materials are SUS304 (AISI304), SUS316(AISI316), SUS316L(AISI316L). Special Alloy Steel Hastelloy, Monel, Inconel are acceptable base on customer's requirement.

The standard sizes are 500x1000mm,600x1200mm and 1000x1000mm,1200x1200mm. Any size within the above range could be made according to the customer's request.

|

|

|

|

|

|

|

|---|---|---|---|---|---|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note:

1.The filtration layer is decided by the customer as long as the Filter rating is within our specified range.

2.We can also make the mesh with other special structures requested by the customer.

3.The porosity takes that of 40mesh as criteria.

|

Type C Sintered Wire Mesh |

It is sintered by punching plate and multi-layer stainless steel wire mesh. Due to the support of punching plate, it has the higher compressive and mechanical strength. It is mainly used in food, beverage, water treatment, dust removing, pharmaceutical, polymer, etc. It can be processed into various filters: tube, disc and sheet. The thickness of the punching plate and the structure of the wire mesh can be customized according to the user's requirements.

The material of the punching plate is SUS304 (AISI 304), and that of the wire mesh is SUS316 ( AISI316) or SUS 316L(AISI316L).

The standard sizes are 500x1000mm, 600x1200mm and 1000x1000mm, 1200x1200mm, and any size within the above range can be customized according to the customer's requirement.

|

|

|

|

|

|

|

|---|---|---|---|---|---|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note:

1.We can choose the filter layer by the customer's needs within the filter rating.

2.Other special structures can be made to the customer's need.

3.The porosity is based on 20u filter layer.

|

Type D Sintered Wire Mesh |

Type D sintered laminate is overlapped and stacked up by 2 or 3 layers of plain dutch woven wire mesh with equal hole size, after vacuum sintering, pressurizing and rolling. It has the average pore size and steady air permeability. This kind of material can be widely used in powder transport, laboratory fluid bed, driers and coolers.

The standard materials are SUS304(AISI304),SUS316(AISI316) ,SUS316L(AISI316L).Special Alloy Steel Hastelloy ,Monel ,Inconel are acceptable base on customer's requirement .

The standard sizes are 500x1000mm,600x1200mm and 1000x1000mm,1200x1200mm, and special size in range can be finished as requirement.

|

Pleated Filter Elements |

Main filter media of pleated filter elements are stainless steel sintered fiber web and stainless steel weaving wire cloth.

1.High porosity rate.

2.Big filtration area.

3.good dirt holding capacity.

4.Used repeatedly after chemical cleaning.

Mainly used in filtration of high molecular polymer, drug, hydraulic oil, water treatment , hot gas, etc.

|

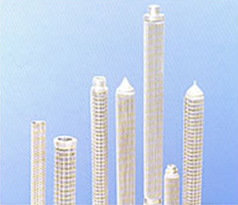

Cylindrical Filter Elements |

Main filter medium of cylindrical filter elements is five-layer sintered wire cloth, filter rating is from 0.5 to 200micron.

1.Boast of good permeability.

2.Easy cleaning.

3.High strength.

4.Good corrosion resistance.

5.Durability.

6.No immigration of materials.

Cylindrical filter elements are mainly used in filtration of polyester, oil products, oil products, chemical industrial products, pharmaceutics, also can be used in filtration of water and gas.

|

Disc Filters |

Disc filter is perfect filter element of machine used in filtration, washing,drying. The rating range from 0.5 to 200micron, in a diameter from 200mm to 3000mm.

1.Good strength.

2.Accurate filter rating.

3.Long life-span.

4.Repeatedly cleaning.

Disc filters are widely used in pharmaceutics, food, chemical industries and polymers.

|

|

Pleated filter Elements |

|

|

Cylindrical Filter Elements |

|

|

Disc Filters |

King Filtration, USALiquid Filters including Filter Bags, Wound Cartridges, Pleated Media Filters, Resin Bonded Cartridges, Melt Blown Depth Filters, Metal Filter Cartridges, Water Filter Cartridges, Membrane Filters, Filter Capsules.

Filter BagsAll standard style liquid filter bags available in Polyester , Polypropylene, Nomex, Nylon, Anode, Cotton, Teflon, Special materials available upon request .

Wound CartridgesWide range of fibers selections and micron ratings make these cartridges an economical choice for filtration of all types of chemicals, water, vegetable and petroleum oils, solvents.

Resin Bonded Fiber FiltersIdeal for filtration of paints and coatings, adhesives, and other viscous fluids.

Pleated Media Filters► Excellent filtration efficiency , choice of materials and micron ratings make this filter an excellent choice.

Bonded Fiber Filters► Melt blown fiber depth filters are economical and offer superior filtration efficiency.

Metal Filters► High efficiency metal fiber filter cartridges in pleated and cylindrical designs. |

|

The filters of various types of FilterApplications

Element materialsStandard elements are furnished with a polyester filter medium. Optional filter materials available include nylon, fiberglass, cotton, polypropylene, Nomex, rayon, wool, Dacron, Teflon and wire cloth providing an application range from sub-zero temperatures to 1000°F. |

|